~ We Provide You With The Vision of Your Equipment Beyond The Capabilities Of The Human Eye ~

~ Via High Resolution Infrared Technology ~

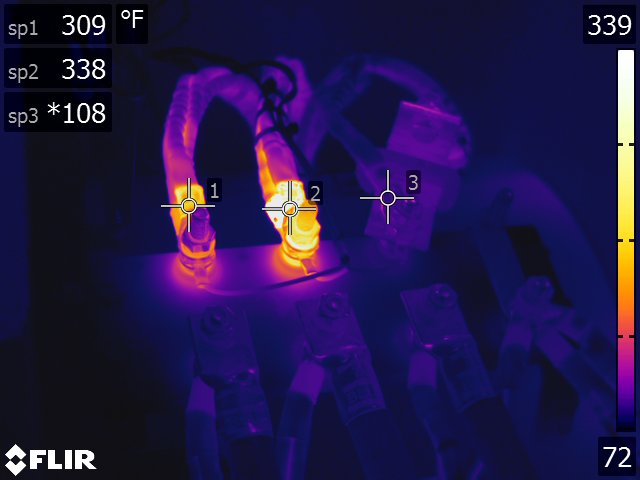

Cascade Thermal Imaging electrical systems infrared inspections provide infrared imagery and the data that reveals potential equipment failures before they become potentially costly problems.

Our electrical systems infrared inspections provide you with a “Predictive Maintenance” capability and our exceptional and unparalleled (ASPECT) IR inspection and reporting software dove tails into MPluse, MindSphere, GEPredix & other Computerized Maintenance Management System (CMMS) streamlining maintenance processes, management and planning, helping you ensure consistent performance and increased efficiency.

Our IR inspection team and our inspection procedures surpass industry standards and place us in a class heads and shoulders above the pack. Additionally, our IR inspection and reporting software is unique beyond measure, exceeds the industry standards and sets us miles ahead of all competition in more than satisfying the needs of the insurance industry.

And as the primary benefit of including a thermographic survey in your preventative/predictive maintenance program is to have the ability to monitor the historic thermal trends over time (Schneider Electric Data Bulletin – Infrared Thermographic Inspection Guidelines – 0110DB0302R6/04) and understanding that most IR reports provided today fall short, in providing this information. Cascade Thermal Imaging provides Historical Trending capabilities on all IR inspections giving you the necessary information required to evaluate and understand the historical trends of your equipment’s functionality over time.

Persons Performing Infrared Inspections Require Special Training, Certification and Most Importantly Experience!

The credibility, expertise and experience of our Infraspection Institute Certified Level III Thermographers have helped our customers avoid equipment damage, reduce fire risk, improve safety, acquire discounts on insurance premiums and save millions of dollars in unplanned outages and down time.

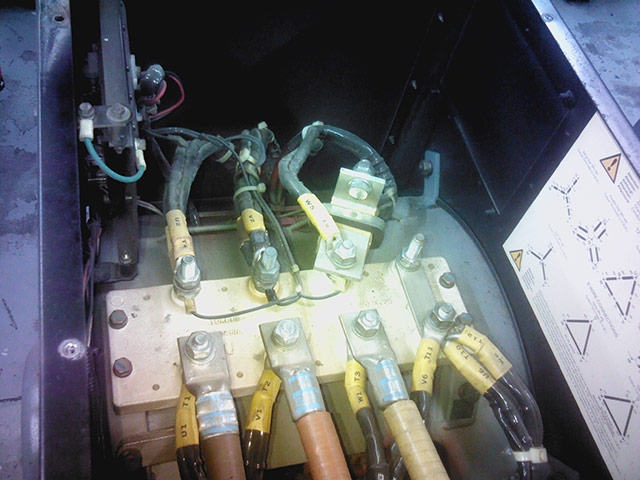

The combination of our infrared technologies, our experience working on, installing and inspecting commercial electrical systems coupled with our exceptional reports backed with careful considerations and due-diligence, no nonsense policy, cost saving recommendations and simple common sense communication allows us to deliver the highest caliber inspections of commercial, and industrial electrical systems without compromise And our high-resolution infrared inspections camera technology provides us the ability to inspect a wide range of electrical and mechanical systems.

Electrical Infrared Inspections Cover a Variety of Applications

- Large and small industrial sites

- Manufacturing plants

- Food, beverage & agriculture facilities

- Petro Chemical & refineries

- Cold Storage facilities

- Hospitals and healthcare facilities

- Property management companies

- Commercial Real Estate management companies

- Aerospace industry manufacturers & parts suppliers

- Local & regional government agencies, utilities

- School boards and universities

- Construction, engineering & architectural firms

- U. S. Naval Vessel Electrical Inspection/maintenance

- Data Centers

- Distribution centers

- Forestry Industry mills & hardwood suppliers

Electrical Engineering Services - Arc Flash Studies & Labeling | Power Systems Studies

Cascade Thermal Imaging provides customers with Arc Flash Hazard Assessment services for improved safety and emergency repair prevention. We deploy highly experienced technicians with 20 years’ experience providing Power Systems Analysis/Engineering Power Studies to companies in a variety of industries.

Arc Flash Hazard Analysis | Power Systems Study

- Arc Flash Study & Labeling

- Short Circuit Study

- Load Flow Study

- Coordination Study

- Power Quality Study

- Ground Grid Study

- Motor Starting Study

Sales And Installation Of IRISS Infrared Windows

Pricing for IR Windows is provided via on-site requirement and measurement consultation.

Professional installation is project managed and conducted by experienced CTI technicians utilizing 01-Journeyman electricians from licensed electrical contractors.

The Goal Of Infrared Inspections And Our Services

The goal of our IR inspections is to ascertain the health, functionality and expected longevity of your equipment under your normal operational conditions. We can provide a predictive level of maintenance protection which can identify equipment within your systems that may present problems with reliability and enable you to develop a predictive plan of action for repairs based on identified and verified findings.

Cost reductions in maintenance, inventory, and workforce personnel have historically been early areas to experience cost cuts. Although it does impact the bottom line, this approach is a band aid and offers merely short-term relief. It does nothing to reduce the stresses on electrical system components. Ignoring routine maintenance only perpetuates failures which are sure to come. For instance, if you operate a transformer at its threshold temperature you will reduce the lifespan of that transformer by 50%.

The goal of course should be to seek out the most technologically advanced, state-of-the-art instruments and technologies to achieve the objective of lowering downtime, increasing revenue, and maximizing equipment life. At a minimum on electrical systems, infrared thermography, voltage/current diagnostics, and visual inspections by trained, licensed, and certified electricians should be the key components of any program.