NFPA 70B Compliance: Keeping Your Electrical Systems Safe, Reliable & Audit-Ready

Infrared inspections for safer, more reliable electrical systems.

What is NFPA 70B?

In 2023, it transitioned from a “recommended practice” to a full standard, making compliance essential for organizations that want to reduce electrical risk, improve safety, and meet insurance and regulatory requirements.

Why NFPA 70B Matters

-

Protects employees, tenants, and building occupants from electrical hazards

-

Reduces downtime from unplanned equipment failures

-

Demonstrates compliance during audits and insurance reviews

-

Extends the lifespan of critical electrical infrastructure

NFPA 70B Compliance in Washington State

Infrared inspections performed by Cascade Thermal Imaging help facilities demonstrate proactive compliance, support safety audits, and meet insurance and local regulatory expectations.

Who Should Implement NFPA 70B Standards?

Facility Managers

Maintenance Teams

EHS Professionals

Risk & Compliance Officers

Operations & Utilities

Support uptime and grid reliability through regular system inspections.

Property Managers

By implementing NFPA 70B standards, these teams work together to reduce hazards, improve system reliability, and meet compliance expectations.

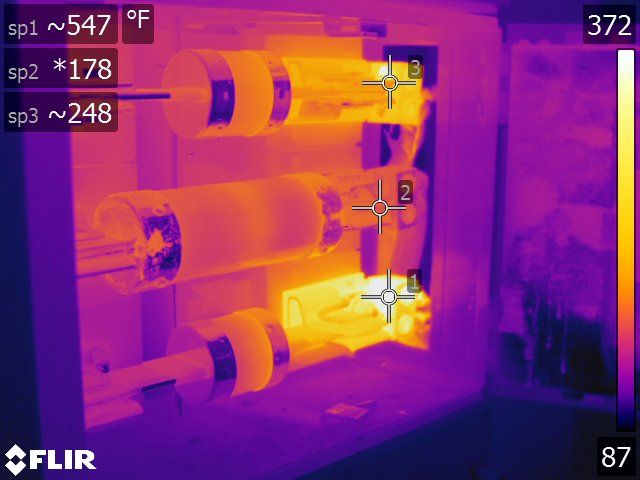

How Infrared Inspections Support NFPA 70B

Infrared thermography is a key diagnostic tool for NFPA 70B compliance. By scanning electrical systems under load, thermographers detect overheating, loose connections, imbalanced loads, and failing components.

All electrical equipment must undergo thermal inspections at least annually, with higher-risk equipment (classified as Condition 3) inspected every six months

(Per NFPA 70B 2023 Edition – Table 9.2.2 Infrared Thermography Scope of Work).

Condition 3 equipment represents assets operating outside normal parameters—showing abnormal temperature rise, deterioration, or other critical anomalies requiring increased monitoring and timely corrective action.

These inspections provide actionable data that allows facilities to:

-

Detect potential failures early

-

Verify electrical systems are operating safely and efficiently

-

Maintain compliance with NFPA 70B, NFPA 70E, and OSHA standards

What Should Your Organization Do Next?

Establish an electrical systems maintenance program that includes infrared thermography inspections.

Maintain complete inspection, corrective-action, and visual Equipment Trending analysis records.

Schedule annual thermographic inspections to support NFPA 70B compliance and long-term reliability.

Why Cascade Thermal Imaging?

- Proven Experience: Over 20 years conducting electrical systems infrared inspections

- Certified Experts: Level III Certified Master Thermographers with advanced training

- Actionable Reporting: Clear, audit-ready documentation aligned with NFPA 70B requirements

- Local Expertise: Headquartered in Redmond, WA and serving facilities throughout Washington, Oregon, Idaho, and Alaska

- Risk Reduction: Detect problems early to minimize downtime, improve reliability, and enhance safety

Does the Updated NFPA 70B Standard Change Inspection Scope or Cost?

With NFPA 70B now recognized as an enforceable standard, many facility managers are asking whether IR inspection procedures, Arc Flash requirements, or pricing must change.

At Cascade Thermal Imaging, the answer is NO.

Cascade Thermal Imaging has always met — and in most cases exceeded — the thermography processes, certifications, and reporting standards outlined in NFPA 70E, NFPA 70B, and adheres to the Infraspection Institute’s Standard for Infrared Inspection of Electrical Systems and Rotating Equipment.

There are no required alterations to our inspection methodology, and the updated NFPA 70B standard does not increase the cost of our infrared thermography inspection services. Arc Flash Studies remain a separate engineering service and do not alter the scope or pricing of CTI’s IR inspection programs.

What Sets CTI Apart

Most infrared providers deliver static, one-time inspection reports.

CTI provides comprehensive Equipment Trending Analysis — building a long-term, data-driven performance history of your critical and essential equipment. This documented historical trending supports insurance reviews, safety audits, and proactive risk management.